1 April 2017

Gantry cranes

The Caulfield to Dandenong Level Crossing Removal Project is using an innovative construction method between Caulfield and Hughesdale that will allow the elevated rail structure to be built while trains are running. This will minimise disruption to Melbourne's busiest rail corridor.

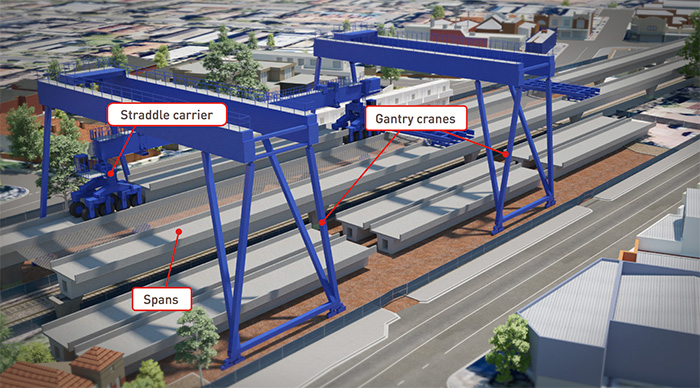

Two gantry cranes, each 30m high and 40m wide, will be based at Murrumbeena Station. The cranes will be used to assemble concrete segments into spans of up to 40m, and lift these onto the elevated structure. The cranes will move backwards and forwards within the Murrumbeena Station assembly area, on purpose built tracks which run parallel to the existing train tracks. Each gantry crane can carry up to 230 tonnes.

The gantry cranes will install the first 8 spans of the elevated rail structure at Murrumbeena Station. Once this section is completed, the cranes will feed the remaining spans into a straddle carrier that will travel between Caulfield and Hughesdale, laying the spans onto the support piers.

Safety is our top priority

The gantry cranes and span assembly process have many inbuilt safety features:

- the cranes will travel at a maximum speed of 2km/hr

- the cranes will remain at all times within the Murrumbeena Station assembly area

- concrete spans will be assembled and stress tested at ground level,

before being lifted onto the elevated structure - a protection screen made of heavy duty steel mesh will be installed along the full length of the gantry crane

- steel protection beams will be in place beneath the spans and the straddle carrier as they are transported over the rail line

- the straddle carrier will operate beside the tracks, not above, and will be controlled by a specialist operator. The machine has an automated 'off switch' with trigger sensors linked to the operator's cabin.

Minimising impacts

The gantry cranes will operate during both day and night works.

A range of measures are in place to minimise impacts on surrounding areas including the use of low emission generators and noise walls around the assembly area.