A successful reform with recycled plastic conduits

A new specification to allow the use of recycled materials such as plastics in conduits could divert tonnes of waste plastic away from landfill and being put to good use on Victorian transport projects.

The Department of Transport and Planning (DTP) has updated Specification Section 733 to allow the use of recycled plastic in conduit piping and the application of sandwich layer conduit.

650 tonnes of sandwich layer conduits (with recycled plastic) have since been installed at the Shepparton Corridor Upgrade.

At the March 2021 Innovation Showcase organised by ecologiQ, the Plastic Industry Pipe Association of Australia (PIPA) proposed the application of a smart, multi-layer extrusion technology using recycled plastic in conduit piping. This technology is also known as ‘sandwich layer’.

Conduits are installed underground for electrical wiring, traffic signals and communication cabling. It is used to protect wires or cables from moisture, UV light and shield electrical wiring from rodents.

These conduits are to be made up of heavy-duty grade, rigid, solid and colour-coded wall, UPVC conduit complying with Specification Section 733 and AS/ NZS 2053.2. The coloured outer layer is important to identify the specific application of the conduit.

Unlike pressure pipes (e.g., gas and drinking water), conduits are non-pressured pipes. Thus, have a greater flexibility to incorporate recycled materials through the “sandwich” construction.

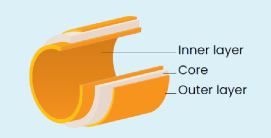

According to the Plastic Industry Pipe Association of Australia (PIPA), this process allows recycled material such as plastics to be used in the core layer of the pipe located between the inner and outer layers of virgin material. Since it is within the core layer, it is not restricted by the colour, density or formulation of a rigid PVC pipe.

PIPA reported that multi-layer conduits have the same performance as single layer solid wall conduits.

A recent inspection undertaken in May this year on the project site has shown that the sandwich conduit fulfilled DoT’s requirements of 95mm mandrel and 95% compaction testing for road use purposes.

Through the connections, platform and support provided by ecologiQ, we now have an alternative use of recycled plastic in civil projects.

ecologiQ runs a series of Innovation Showcases to engage with the recycled material supply chain network to encourage knowledge sharing and identify areas of synergy between material suppliers and transport projects in Victoria. If you have an innovative idea or product that you would like to pitch, please get in touch ecologiq@roadprojects.vic.gov.au. Another round of Innovative Showcase will be scheduled for later this year, stay tune.