Bridge design

The new Echuca-Moama river crossing is made up of 2 new bridges over the Murray and Campaspe rivers, and 2 smaller flood relief bridges. We’ve designed the bridges over the Murray and Campaspe Rivers to integrate seamlessly with the surrounding natural environment. We also installed noise walls to help reduce traffic noise for nearby properties.

The new Murray River crossing measures a whopping 622m across the floodplain and sits 15m above the riverbanks. The bridge consists of 14 separate spans, measuring up to 34m in length. The main span over the river is 115m long. The new bridge across the Campaspe River is 293m long and consists of 8 spans. We've used a 45m long steel box girder to build the main span over the river.

For the other 7 spans, we've used precast concrete super-tee beams. The steel box girder has been selected for the main span across the Campaspe River as it’s 45m length is too long for conventional super-tee beams. We've also built a new walking and cycling bridge, which will provide a safe and scenic journey between Echuca and Moama.

Flood relief bridges

As part of Stage 3, we’ve also built 2 small flood relief bridges over the Murray River floodplain, 1 on either side of the river. These bridges are constructed approximately 500m from each riverbank. They will provide additional hydraulic capacity during large floods, ensuring upstream flood levels are controlled.

Murray River

Building the bridge across the Murray River.

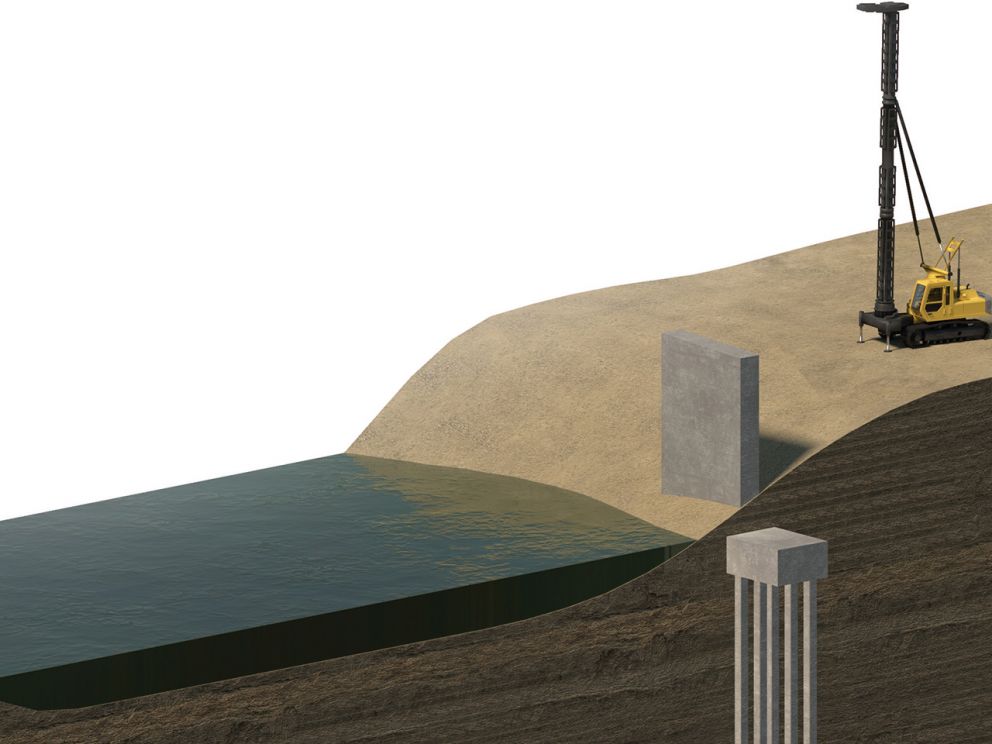

Concrete piles are hammered into the ground at each riverbank, to depths of approximately 35m. The piles help to create a strong foundation for the bridge piers.

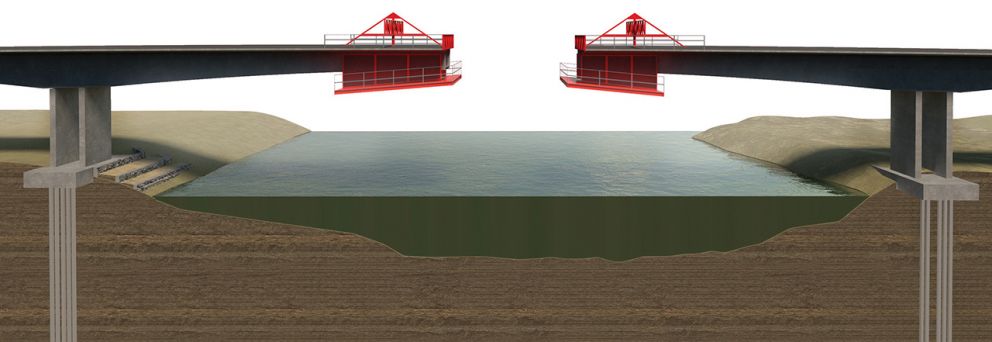

Form travelers are then positioned on top of the bridge piers. Form travelers are concrete moulds that move along rails to build the main span of the bridge.

Campaspe River

Building the bridge across the Campaspe River.

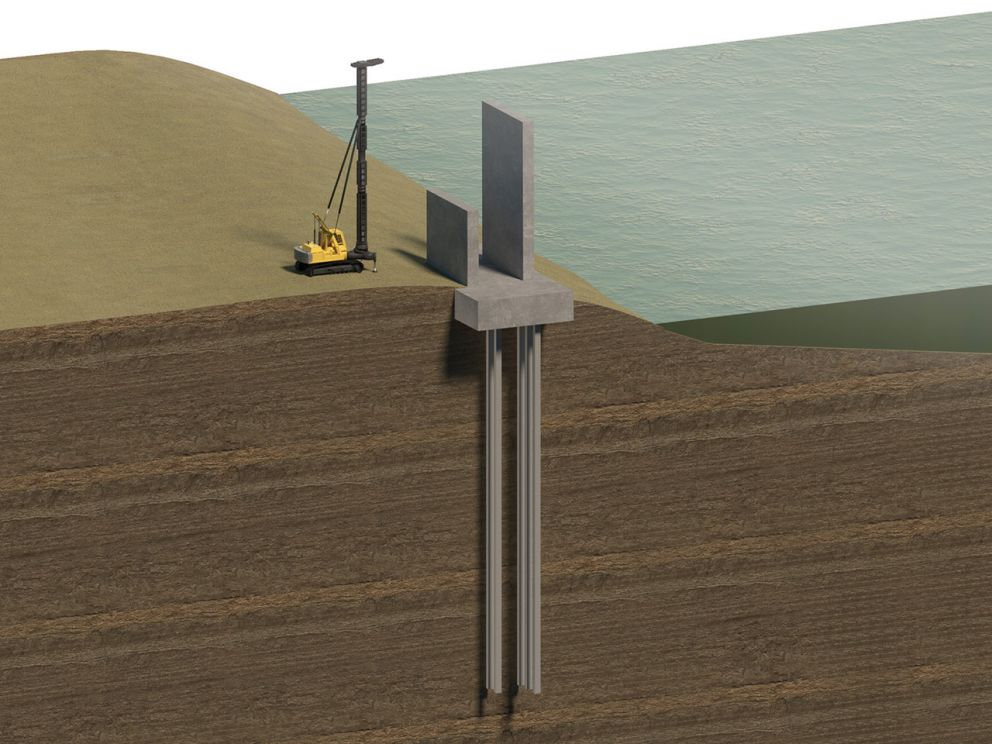

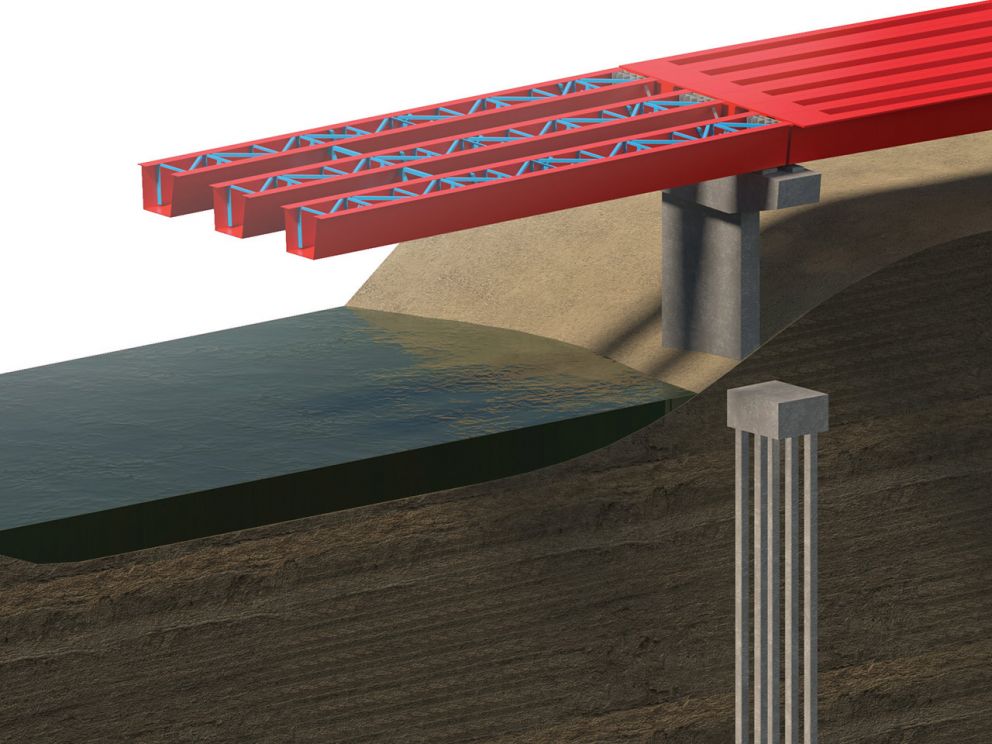

Concrete piles are hammered into the ground to depths of approximately 35m using a piling rig to create a strong foundation. Thick concrete slabs (known as pile caps) are then installed across the piles to link them.

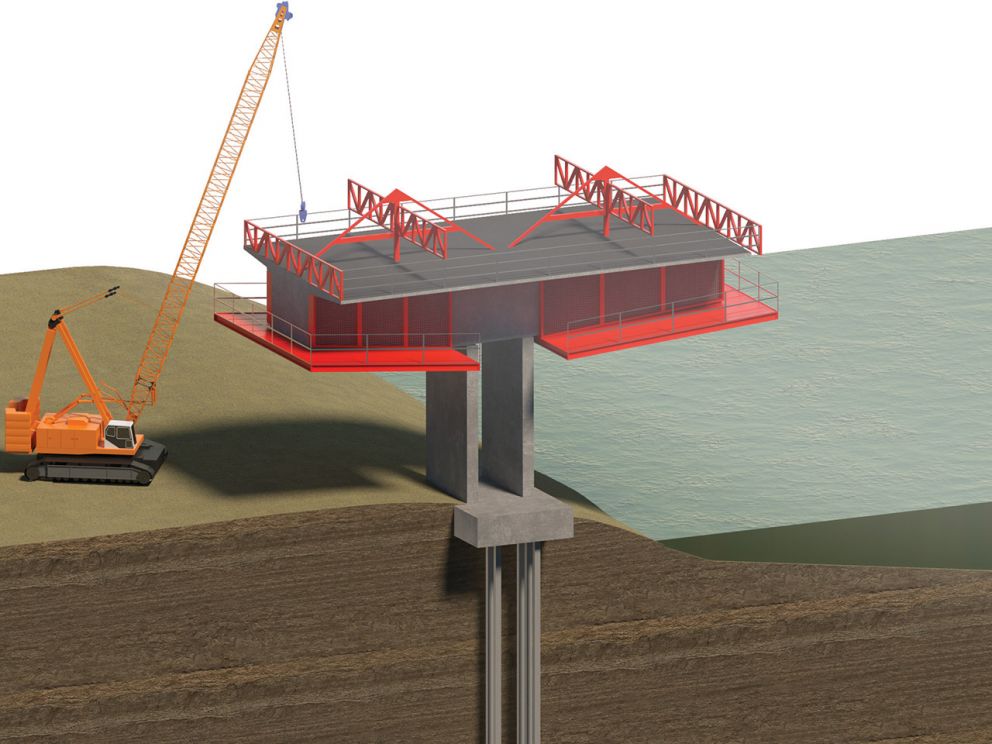

The bridge piers are then built using specialised braced forms and steel reinforced cages. Concrete is then poured into the reinforced cages.

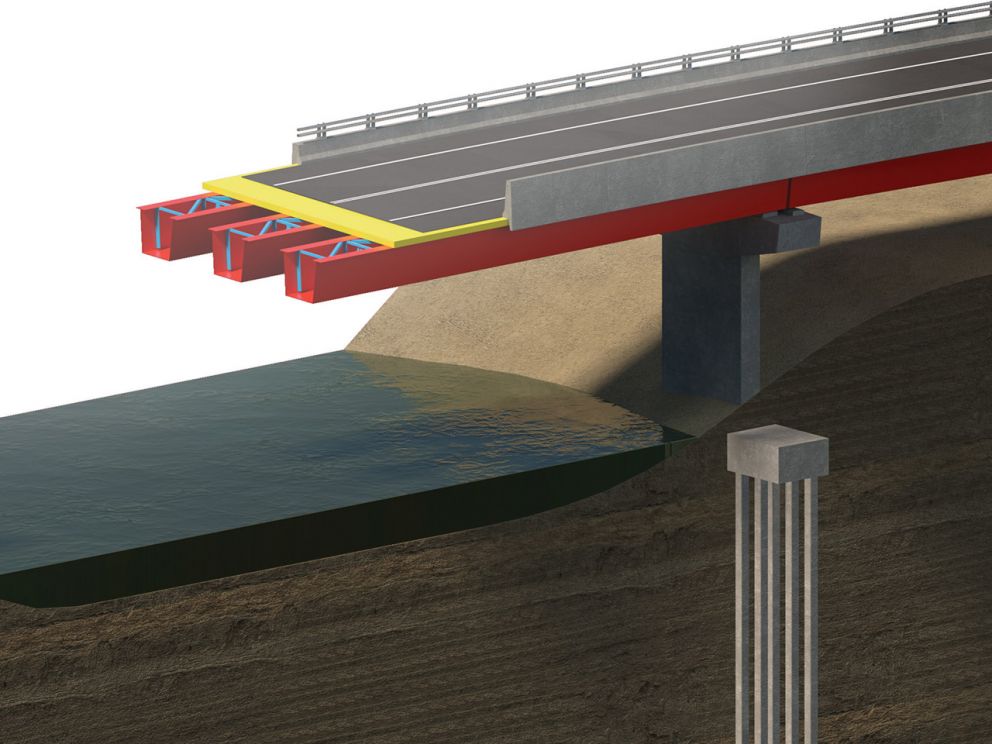

Concrete beams are then installed on top of the bridge piers. Once the beams are in place, a concrete slab is cast on top to create the bridge deck.

While the bridge deck was being built, we also installed drainage, barriers, kerbing and laid asphalt to create the surface of the new road. The final touch involved marking the new road with lines to divide the traffic lanes.