Station construction techniques

To avoid disruptions to Swanston Street, access shafts up to 11 storeys deep were dug and used to transport machinery, equipment and workers underground to excavate the new stations.

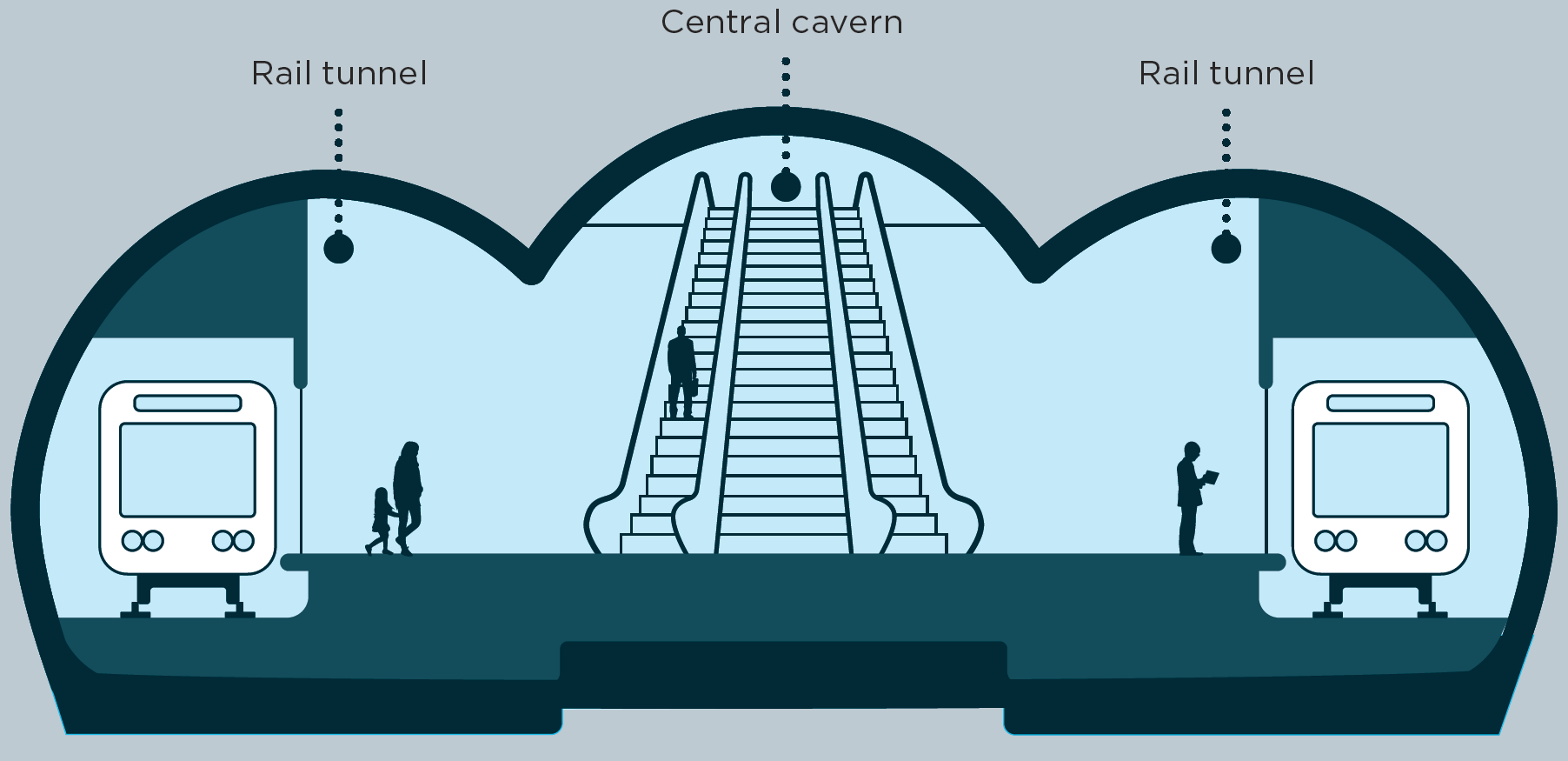

Both State Library and Town Hall stations are 'trinocular' caverns. Roadheaders created 3 overlapping tunnels to create a wide open space for both concourse and platforms. The total platform width at the CBD stations is around 18m – some of the widest underground metro platforms in the world.

Trinocular cavern, indicative only.

Trinocular cavern, indicative only.

The other new stations, Arden, Parkville and Anzac, were built with a cut and cover method, excavating straight down from the surface and covering the station with a concrete deck.

Acoustic sheds

Temporary acoustic sheds up to 20m high were used during Metro Tunnel construction to minimise noise, light and dust impacts on the local community. Custom built sheds were installed at City Square, Federation Square, Franklin Street, A'Beckett Street, and St Kilda Road.

Tunnelling works

Along its route, the depth of the Metro Tunnel is up to 40m. The deepest point is under Swanston Street, at the northern edge of the CBD, where the new tunnels pass under the existing City Loop tunnels.

As we built the tunnels we:

- navigated existing underground infrastructure – including the City Loop, CityLink tunnels and services such as water, gas and electricity

- excavated through a range of challenging geological conditions including rock, sands, clays and silt

- tunnelled under 2 significant waterways, the Yarra River and Moonee Ponds Creek

- managed the removal and disposal of around 1.8 million cubic metres of soil and rock

- managed disruption to residents, businesses and public events

- minimised potential impacts on road traffic, pedestrians, cyclists and existing public transport and freight services.

Additionally 26 cross passages were built, smaller tunnels connecting the rail tunnels at intervals of approximately 230m. These cross passages are an important safety feature that allow passengers and emergency services to move between the tunnels in the event of an emergency.

Rail installation

Installation of rail in the Metro Tunnel took about 9 months, and was completed at the end of March 2023.

Crews first began laying 4000 precast concrete panels along the twin 9km tunnels. There are 300 different panel shapes, to account for the varying curvature and elevation of the tunnels as they wind from Kensington to South Yarra up to 30m underground.

The high-performance panels are similar to those used in other world-class metro systems. They require significantly less maintenance compared to conventional surface railway tracks, which use sleepers laid on crushed rock.

After the precast panels were installed, steel rail was clipped on in 165m lengths and then welded together to form a continuous rail line.

Floating slab track has pads underneath which absorb train movements, reducing noise and vibration felt at ground level. In areas of the tunnel where extra protection from noise and vibration is needed, floating slab track has been installed.

Other tunnel equipment

Other tunnel fit-out works include installing electrical and communication cabling, fire safety pipework and signalling equipment.

In total, the 18km of combined tunnel fit-out included:

- almost 50,000 brackets

- 15km of elevated steel walkway for emergency and maintenance access

- almost 500km of electrical and fibre cables

- 16km of pipework to carry fire retardant

- more than 3000 lights.